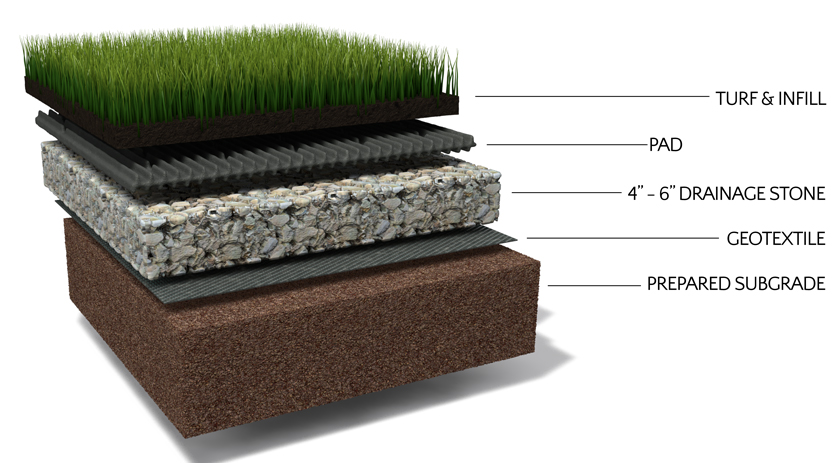

The 15-acre Port Angeles project included a municipal solid waste (MSW) landfill closure system and mechanical stabilized (MSE) wall. The closure consisted of a turf system that is comprised of a structured geomembrane, an engineered turf, and a specialized sand infill or ballast. The foundation of the system is an impermeable, highly transmissible structured geomembrane with aggressive texturing that provides high interface friction valves between the underlying low permeability soil barrier (LPSB) layer and the geomembrane interface.

The engineered turf component gives the system a natural look and feel of grass while protecting the geomembrane from extreme weather conditions for the long term. The closure-turf cover system also used a series of soil layer materials, including a bentonite-soil layer, to minimize the downward migration of water from the cover system into the waste.

Producing a suitable low permeability soil barrier (LPSB) material consisted of mixing screened native soils with a sodium montmorillonite clay-bentonite by mechanical means. The mechanical stabilized (MSE) wall also used the same bentonite-soil admix low-permeability barrier layer to minimize the horizontal migration of contaminated water (leachate) from the waste mass. In addition, the landfill gas (LFG) system was expanded with additional vertical extraction wells and with the abandonment of the existing collection and transmission piping system, and replacement with a new HDPE piping system. Additional construction included landfill gas collection and transmission piping systems, drainage control structures and site access roads. PeakGeo implemented the on-site CQA program, provided full-time inspection, coordinated and performed all construction materials testing, and mobilized an on-site geotechnical soils laboratory. The on-site laboratory was capable of performing standard soils testing, including moisture-density relations, sieve analysis, moisture content, index density, sand-cone density, hydraulic conductivity, free-draining permeability, cylinder-drive density, nuclear density, atterberg limits and visual-manual classifications. The on-site laboratory also performed bonded seam strength and peel adhesion on geomembrane destructive seam samples. The site laboratory conditions are maintained at a temperature of 73.4°F ±3.6°F (23°C ±2°C) and at a relatively humidity of 50% ±5% in accordance with ASTM E 171, Standard Laboratory Atmosphere. PeakGeo joined our teaming partner, Anchor QEA, who served as the certifying engineer, construction manager and contract administrator for the project. Anchor QEA also provided the drone flight videos for the Port Angeles project.